Flo-Tek Flowguard CPVC Installation

Installating the Flo-Tek Flowguard CPVC system is as easy as 1 2 3! It is so easy to install, thus saving contractors and plumbers time on site.

TOOLS NEEDED

- A Pipe Cutter

- A Chamfering Tool

- CPVC Solvent Cement

The main degradation process is dehydrochlorination, not oxidation. This dehydrochlorination, whilst slightly accelerated by U.V., does not break down the polymer chains to any significant extent after outdoor exposure, being mainly limited to a surface discolouration effect.

However, for extra protection for CPVC pipes which are directly installed under harsh sunlight conditions, Flo-Tek recommends protecting all pipes and fittings installed outdoors to prevent any kind of mechanical damage to the system.

CUT

- Cut the pipe squarely using a wheel-type plastic tube cutter.

- Use a chamfering tool or file to remove burrs and filings from the inside and outside of the pipe.

- Wipe any dirt or moisture from the fitting sockets and piping end.

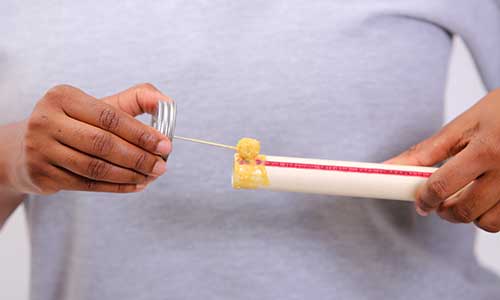

GLUE

- Apply a heavy, even coat of cement on the pipe end.

- Apply a thin coat inside the fitting socket.

JOIN

- Immediately insert the pipe into the fitting socket.

- Rotate the pipe a quarter turn while inserting and hold for 30 seconds.